Simulation of an Industrial Axial Fan with CONVERGE

Industrial fans play a critical role in maintaining safe working environments, controlling temperatures, and ensuring proper airflow in diverse settings such as factories, power plants, mines, and transportation. Because of their large size, building prototypes for every design is impractical. Instead, simulating each design to study airflow patterns, velocity profiles, and pressure drops can help assess the fan’s performance under different operational conditions to find the most energy efficient design(s).

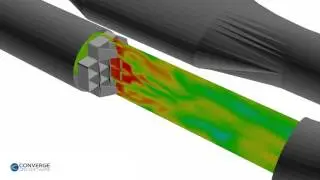

In this study, we simulated an industrial axial fan to analyze the pressure fluctuations and airflow across the rotating blades. CONVERGE’s autonomous meshing automatically creates a high-quality mesh at runtime, eliminating the need for manual meshing. This feature effectively handles simulations involving moving geometries because it regenerates the mesh at each time-step depending on the object’s motion. While some CFD tools move the mesh to accommodate moving components, which can degrade the overall mesh quality and cause instability, CONVERGE’s unique cut-cell approach eliminates mesh-related instability. Additionally, we employed CONVERGE’s actuator line model (ALM) feature, which eliminates the need for modeling the fan blades by simplifying the 3D blade surfaces to 1D lines. This method significantly speeds up the simulation, while still accurately capturing the essential physics. CONVERGE’s ALM projects aerodynamic forces anisotropically, which is important for blades with a low span-to-chord aspect ratio. To capture turbulence, we used the Delayed Detached Eddy Simulation model.

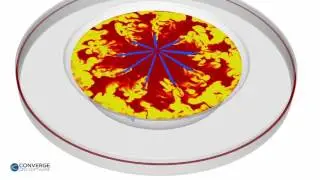

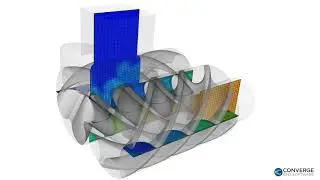

The first view (~0:03) shows the axial fan. The blades themselves, which are highlighted in red, are not actually modeled as a part of the geometry; rather, their effects are captured using CONVERGE’s ALM. In the second view (~0:09), the streamlines represent the flow of air from left to right. These lines are colored by velocity magnitude, from low velocity in blue to high velocity in red. The third view (~0:17) presents a slice along the center, which is similarly colored by velocity. The fourth view (~0:24) displays pressure contours on the slice with red color indicating regions with higher pressure values and green color denoting lower pressures. The mesh lines are shown in black. The fifth view (~0:28) zooms in to highlight the finely embedded mesh.

Convergent Science's CONVERGE is an innovative computational fluid dynamics (CFD) software that eliminates the grid generation bottleneck from the simulation process through autonomous meshing.