Webinar: Simulation for Pipeline Integrity including Welding Process

During pipeline inspections, you may come across several structural changes in pipelines.

Cracks, General/Local Metal Loss, Pitting Corrosion, Stress Corrosion Cracking (SCC), Hydrogen Blisters, HIC, Crack-Like Flaws, Dents and Gouges, Lamination are common changes to be identified in pipelines. Also, weld residual stress play an important role in mechanical response of pipeline joint.

Here are some important questions to consider:

As companies own and operate thousands of miles of pipelines, how can you make sure that you know which sections of the pipelines should be repaired imminently?

How the residual stresses at weld is affecting pipeline mechanical response?

When should you repair and / or schedule maintenance?

What would be the remaining useful life of the component under evaluation?

The VIAS team can help you answer these questions with our Fitness-for Service (FFS) capabilities and project experience. Please join us for the webinar on performing simulations for pipeline integrity.

In our webinar, we will cover the following topics:

Assessment Levels - API 579

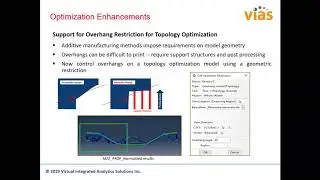

FEA based Level 3 Assessment

Code Based Design by Analysis

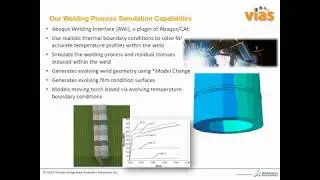

Welding Simulation

FEA based Fracture: Modeling of Flaw

Material Testing Support

Contact us today: [email protected]

Visit our website: www.viascorp.com