Simulation of the Lubricant Flow Inside a Gearbox

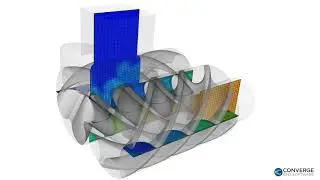

In recent years, environmental concerns have turned more eyes toward gearbox efficiency. There are many possible reasons for power loss in a gearbox, including hydraulic loss caused by churning, windage, pocketing, and/or cavitation. CFD can help anticipate these load-independent losses and optimize gearbox design to increase its efficiency. In this CONVERGE simulation, we used our volume of fluid modeling to capture the oil-gas interface inside the gearbox. We also used RANS modeling to capture turbulence. The first view in the video shows the lubricant churning and spreading inside the gearbox. The second view shows the velocity contours on the lubricant-air interface. The third view shows the velocity contours on the surface of the gears, with blue representing a low velocity value and yellow representing a high velocity value. The final view shows the mesh, colored by velocity magnitude, passing through the axis of the gears. CONVERGE’s autonomous meshing with Cartesian orthogonal cut-cell approach can both capture the complex moving geometry with ease and decrease overall runtime. CONVERGE’s Adaptive Mesh Refinement adds cells only in the areas required, optimizing cell count and reducing the cost of the simulation.

Convergent Science's CONVERGE is an innovative computational fluid dynamics (CFD) software that eliminates the grid generation bottleneck from the simulation process through autonomous meshing.