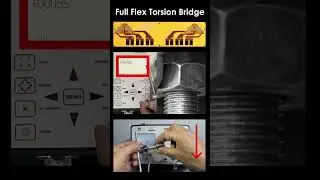

Lattice Boom Crawler Crane (Stress Analysis and Force Measurement)

For experimental stress analysis applications, Advanced Sensors Technology strain gauges are used to validate the design assumptions for Lattice Boom Crawler Cranes, and to assure that the crane will perform as the designer and operator intended. For these uses, the engineers bond the strain gauge to the crane structure to test and measure applied service loads. Using a strain gauge with one of Micro-Measurements’ data acquisition and analytical instruments, we can quickly and accurately validate the performance of the crane.

In addition using Advanced Sensors Technology strain gages, OEM transducer manufacturers can make everything from pharmaceutical balances with weighing resolution in milligrams to weighing systems that mount on heavy lifting cranes capable of measuring forces of hundreds of tons. In the case of the crane onboard weighing system, the strain gauge based transducer / display can inform the operator if the load being raised is within the safe limits of the crane and will not cause the crane to tip. In one of the common applications, the strain gauge is installed between the crane hook and the cables; and the strain gauge output is sent back to the crane cab via a strain indicator and recorder. The DAQ or strain indicator digitized (Analog to Digital process) provides a real time display of the weight on the hook and can be programmed to sound an alarm or show an alert on a screen if the load is too heavy or close to a threshold. This allows the operator to stop the lift before the crane is toppled or damaged.